Hunter Industrial North Dayton Salt Dome

The Resource Conservation and Recovery Act of 1976 (RCRA) and the more recent Hazardous andSolid WasteAmendments of 1984 (HSWA) have mandated the development of innovative technologies for the destruction, treatment, and/or secure containment of hazardous waste as an alternative to land disposal methods currently in use. The Hunter Industrial Facilities, Inc. (HIFI) North Dayton Containment Facility is designed to use innovative technology that will meet the objectives and demands of the hazardous waste regulatory program and the needs of industry for a securewaste containmentfacility. HIFI has developed and engineered a facility suitable for treated wastes and rawwaste streamsthat cannot be further treated, recycled,incinerated, or eliminated by improvements in the manufacturing process. The concept of the North Dayton Containment Facility is to isolate treated andsolidifiedwaste by containment in a stable geologic salt formation, preventing the release of hazardous constituents into the environment.

The need for secure, long-term hazardous waste disposal facilities that ensure protection of human health and the environment has increased in recent years for several reasons. The enforcement of new federal and state pollution control laws and regulations has expanded the universe of wastes regulated as hazardous and has provided for the imposition of fines to remove hazardous compounds from wastewater discharges and air emissions. The intensified regulation and treatment of such discharges has resulted in increasing the volume of controlled hazardous waste. The regulation of a greater number of generators under HSWA and the cleanup of abandoned disposal sites under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) amended by the Superfund Amendments and Reauthorization Act of 1986 (SARA) have also increased the volume of hazardous waste requiring disposal and the resulting demand for environmentally secure disposal facilities.

The disposal method developed by HIFI involves thesolidificationand stabilization of industrial and commercially generated regulated waste and its placement in caverns constructed deep within a geologically secure salt dome. This waste management concept uses the following engineered and natural geologic protection systems.

1. Waste is solidified to reduce the mobility of regulated constituents and improve handling characteristics.

2. Solidified waste is deposited in a dry, geologically stable, solution-mined repository, a salt cavern.

3. The repository is isolated from all groundwater aquifers by the impermeable salt formation and is constructed below the deepest potable aquifer and underground sources ofdrinking waterin the area.

4. Solidified waste in caverns is permanently contained away from the erosional effects of rain, wind, and freeze-thaw cycles.

5. Solidified waste is permanently isolated from human activities and inadvertent intrusion.

6.Salt is self-healing, thereby providing its own inherent mechanism for perpetual maintenance.

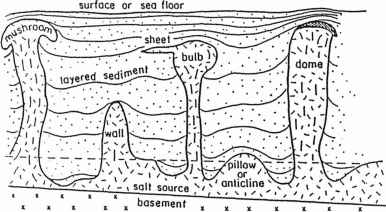

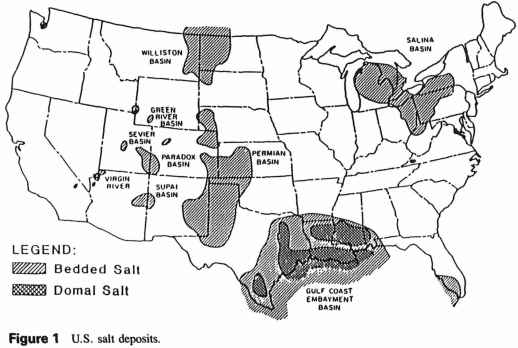

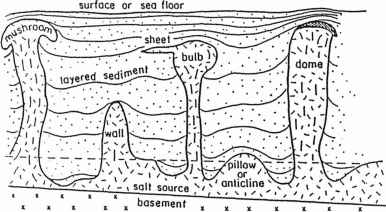

Salt formations, both domal and bedded strata, originated from saltwater seas an estimated 150-300 million years ago. Repeated cycles of evaporation and recharge created the regional accumulations of bedded salt with which we are all acquainted (Figure 1). Eventually the cycles of salt deposition ended and were followed by cycles of sediment deposition. After millions of years this sediment deposition and other geologic and climatic influences culminated in the salt formations encountered today.

Throughout this period, salt strata experienced a variety of temperature and pressure influences determined in part by their depth and their proximity to interior or coastal areas of continents. Influences occurring at the relatively stable interior areas tended to consolidate the salt into horizontally stratified formations termed bedded salt. In the less stable coastal areas, buoyancy differentials causedvertical movementof the salt formation, forcing it upward

salina BASIN

WILLISTON BASIN

SEVIER盆地

iPERMIAN I BASIN

PARADOX BASIN

VIRGIN RIVER

SUPAI BASIN

LEGEND:

VM/A Bedded SailDomal Salt

GULF COAST EM8AYMENT BASIN

Figure 1 U.S. salt deposits.

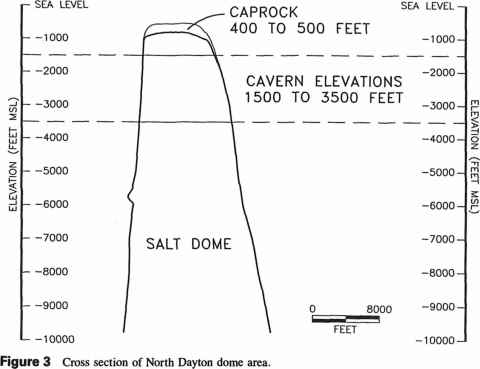

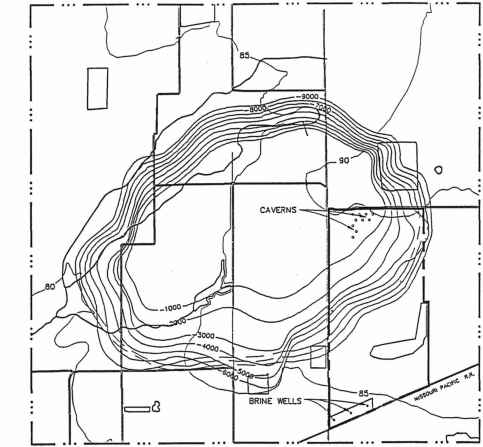

through the overlying sediments. Salt beds of the coastal plains tend to be deeper than those encountered in interior areas, and at this additional depth, temperatures as high as 400°F greatly reduce the viscosity of the formation, adding to its relative buoyancy and vertical flow. This flow, arising from the salt's plasticity, functions also as a mechanism that expels impurities, including liquids (brine) and solids (rock). Over geologic time this resulted in the formation of underground mountains of homogeneous pure salt (Figure 2). The North Dayton dome, which actually resembles a column (Figure 3), extends to a depth of 45,000 ft below land surface and has an area of more than 4 mi2 at its top (Figure 4). It is estimated that there may be 500 similar structures, termed salt domes, in the Gulf Coast region.

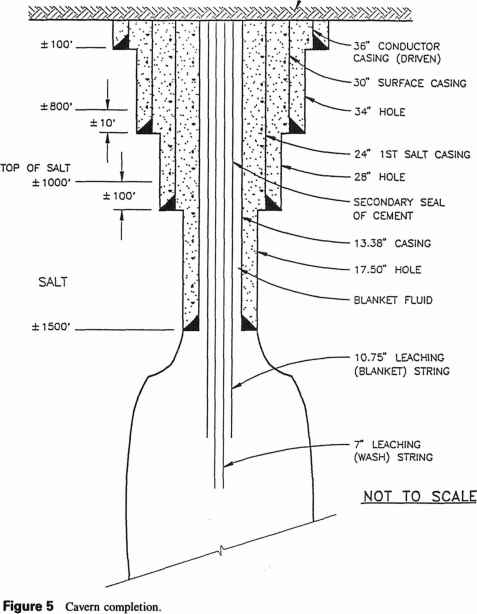

是用来证明溶液采矿技术create the caverns. Fresh water is injected into the salt formation under controlled conditions to dissolve salt and leach the caverns. The water and salt combine to form a brine that is pumped from the cavern and injected into a saline aquifer using conventional deep well injection techniques. Cylindrical caverns 125 ft in diameter will be completed approximately 600 ft below the surface of the salt and extend an additional 1800 ft deep (Figure 5). The approximate depth below land surface to the top of the salt is about 900 ft. Therefore, the tops of the caverns will be created about 1500 ft below land surface, with the bottoms of the caverns 3300 ft below land surface.

All waste will be solidified, cured, then pulverized on-site prior to disposal. During the solidification process, waste will be mixed with fly ash, cement, and other additives. The solidified, pulverized waste will be pneumatically conveyed into the underground caverns. After a cavern is filled with solidified waste, it will be sealed permanently with cement grout, the open bore hole filled with salt, and the cased hole cemented to the surface.

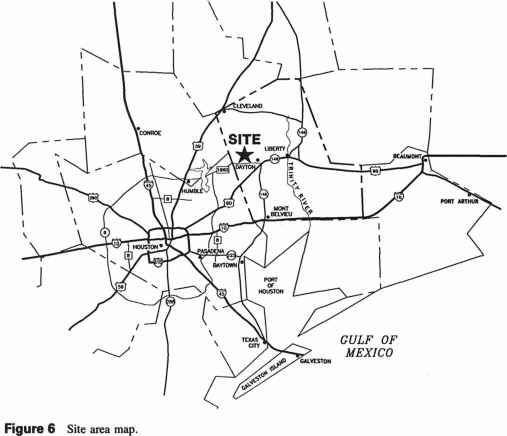

Solution-mined caverns in salt formations are currently being used by the U.S. Government to store crude oil. Since 1978, the U.S. Department of Energy has stored more than 750 million barrels of crude oil in solution-mined salt dome caverns for the Strategic Petroleum Reserve. Contractors engaged by HIFI have been responsible for the development of these crude oil storage caverns for DOE. These same contractors, who will be developing HIFI's caverns, have well over 1000 man-years of experience in this process. In addition to the government's use of salt dome caverns for secured storage, private industry operates over 1800 caverns in the United States for the storage of liquid petroleum products, petrochemicals, andbet雷竞技 . TheNorth Dayton salt domealready contains two natural gas storage caverns that have been in operation for over 4 years for the benefit of a local utility.

-

- Figure 2 Salt structures.

NORTH SOUTH

European countries also use caverns in salt formations as containment sites for hazardous and nuclear wastes. Based on the fourth amendment to the law of waste disposal of the Federal

Republic of Germany, certain West German states now require the disposal of irreducible solid waste in salt caverns.

Domal salt is attractive as a containment medium because of the following characteristics.

1. Salt in salt domes is uniquely homogeneous. During salt dome formation, portions of the surrounding bedded materials, notably clay, carbonate, and anhydride, are selectively sorted and displaced by buoyancy and plasticity mechanisms as development of the salt dome proceeds toward the surface.

2. Domal salt generally has no intrabedded sedimentary layers of impurities to serve as pathways for water to enter the body of the dome or as discontinuities along which cavern roof cave-ins may occur.

3. Domal salt is geologically stable and has been stable for millions of years.

4. During formation, salt domes evolved through repeated stages ofrecrystallizationthat left these structures dense and impermeable to fluids.

5. A relatively impermeable cap rock layer often develops between the salt dome and the overlying sediments, thereby further isolating the salt stock fromshallow groundwaterinfluences.

6.盐穹顶是足够大的, typically occupying several square miles, that lateral and vertical salt buffers exist around the actual repository. A cavern repository would be substantially separated from the nearest aquifer, typically by hundreds of feet of salt.

7. Salt in dome structures is a nonreactive material and will not react with solidified hazardous waste.

CAVERNS

BRINE WELLS

4000 2000

4000

SCALE

FEET

IMPROVED ROAD

PROPERTY BOUNOARY

CONTOUR WITH ELEVATION (FEET MSL)

SALT DOME CONTOUR WITH ELEVATION (FEET MSL)

Figure 4 Structure map.

NATURAL GROUND

NATURAL GROUND

The design of the HIFI disposal caverns is in compliance with the Texas Injection Well Act and regulations and guidelines of the Texas Water Commission Underground Injection Control program relative to well construction, siting, and monitoring. Multiple cemented steel casings prevent any contact between waste and the upper freshwater aquifers. Monitoring of operational parameters ensures the mechanical integrity of casings and verifies that excessive pressures are not experienced during cavern development and disposal operations.

Continue reading here:Related Operations In Salt Formations

Was this article helpful?